Finding Failures with Acoustic Emission

What is Acoustic Emission?

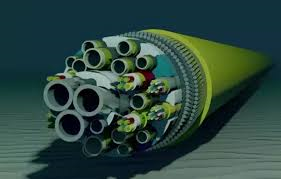

Acoustic emissions (AE) are ultrasonic transient waves found within a material, caused by the release of energy when a crack or delamination occurs. AE is considered a form of non-destructive inspection (NDI) and ultrasonic testing (UT). By utilizing the speed of sound in a particular material and the time difference between sensor readings, Metcut’s AE systems can find the location of the source in a 2D or 3D manner. Acoustic Emission sensors are vital tools when determining integrity of various materials and structures found both in R&D as well as already existing buildings. AE is typically used in materials testing where the source of a crack or flaw can occur anywhere within the test article. Another application of acoustic emission is monitoring critical infrastructure of buildings that are already standing; an example being the London Infrastructure with over 300 sensors monitoring for cracks.

The Benefits

This method of crack detection is attractive because it is not invasive or destructive to the materials / structures you are observing. AE also requires no current to pass through the material like typical crack-growth PD systems would. By utilizing multiple sensors, you can triangulate the source of an internal or external failure in a 3-dimensional manner. Materials tests where anisotropic materials or structures with abnormal geometries benefit greatly by collecting AE data. In 2020 Metcut was contracted to test some full-scale aircraft wings where AE was used to measure the energy released from “pops” during testing. The energy release measured was used to determine whether substantial damage had occurred.

Authored By: John Muskopf. For more information on this subject or other testing solutions, contact them @ JMuskopf@Metcut.com