Triaxial Shaft Fatigue Testing

Driveshaft Life Evaluation

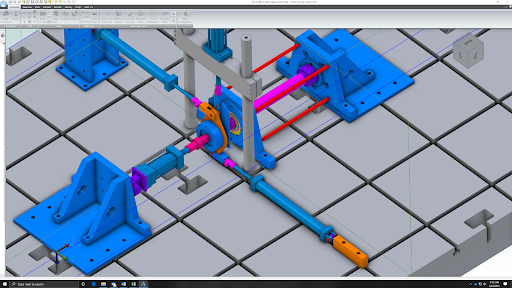

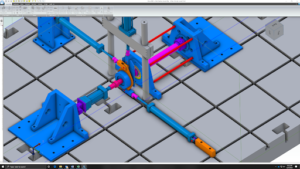

The drive shaft (pink) required evaluation for bending over a bearing while applying normative torque and axial tension and compression within its life cycle.

Unique, independent laboratory capabilties

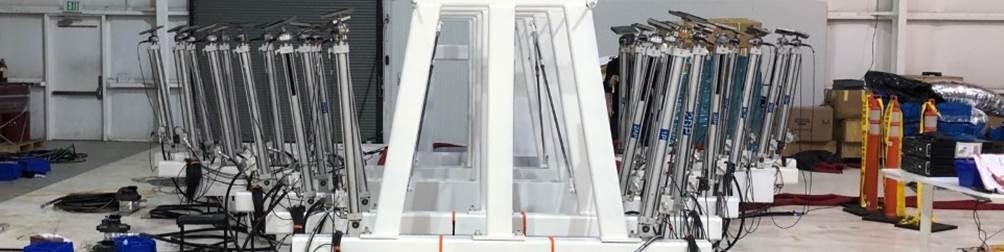

Metcut provided the design and manufacturing services for the test station and fatigue testing utilizing our MTS multi-channel servo controller to drive the testing. Strain gages were applied to the shaft for life degradation evaluation. The four (4) load input axis and associated displacements as well as the applied strain gages were periodically recorded in high speed “burst” periods. These data burst records were sequentially compared for shaft performance degradation throughout the lifetime of the test. The fixturing at the nose of the shaft required a unique spherical roller bearing to accommodate the motion of the shaft in combined bending, rotation and axial motion under load.

Authored By: Bill Grieszmer, Chief Engineer. For more information on this subject or other testing solutions, contact Bill at wgrieszmer@Metcut.com