Simulating Supersonic Loads With 27 Actuators

We Have a Supersonic Simulation on Our Hands…

In early 2020, Metcut was contracted to apply its experience of testing aircraft structures to a newly developed supersonic commercial jet prototype. Testing was conducted on the aircraft before test flights, where a pilot would be flying at speeds that create some immense G-forces. As a result, a high degree of caution was required to ensure the prototype wasn’t damaged due to overloading the structure. Fortunately, the client recognized Metcut’s capabilities, care and control required for testing the one-of-a-kind aircraft.

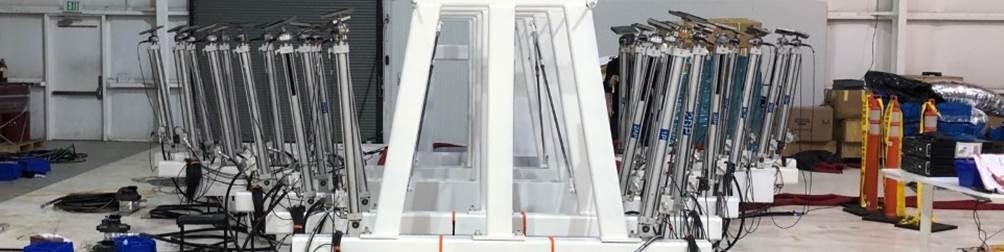

Testing was conducted onsite in a hangar located far from the Metcut Cincinnati location. To accomplish this, a shipment with a 20 GPM hydraulic pump, 27 actuators, 100+ sensors, 150+ cables, 500+ ft of hoses, and an MTS Flex controller met the crew of engineers and technicians at the hangar.

Upon arrival, the Metcut structures crew did what they do best and built a unique test system around the one-of-a-kind test article.

If you are looking for an independent test lab with an extensive collection of capabilities that understands how to test your product safely, you have found it. Metcut is an employee-owned company and has been since 1976. Making 45+ years of customer driven quality, without the need to please investors. Metcut is focused on what is important; Offering clients unmatched trust, credibility, quality, and commitment in testing their precious parts when it matters most.

Authored By: John Muskopf