Digital Image Correlation

FEA Validation using Digital Image Correlation

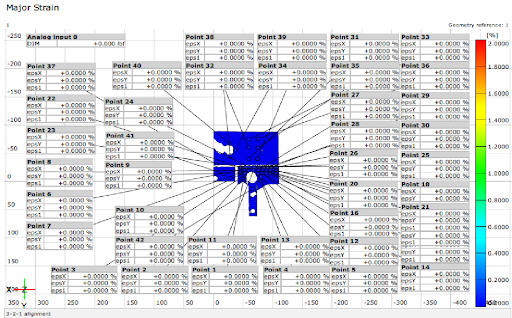

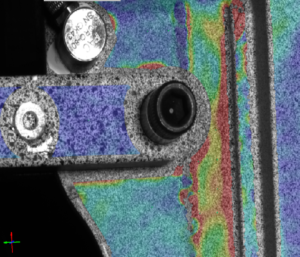

Metcut provides services to a wide variety of industries, most of which use Finite Element Analysis (FEA) to validate designs. These designs are typically tested in real-life to determine the validity of the FEA. While comparing a few locations to the model is good, having a full field strain reading is best when comparing the two. DIC can produce heat maps that can be directly compared to heat maps presented in FEA. DIC is currently accepted as an optical extensometer system and has established use in many large aerospace, space, oil & gas, transportation.

Metcut provides services to a wide variety of industries, most of which use Finite Element Analysis (FEA) to validate designs. These designs are typically tested in real-life to determine the validity of the FEA. While comparing a few locations to the model is good, having a full field strain reading is best when comparing the two. DIC can produce heat maps that can be directly compared to heat maps presented in FEA. DIC is currently accepted as an optical extensometer system and has established use in many large aerospace, space, oil & gas, transportation.

COPIOUS AMOUNTS OF DATA COLLECTION

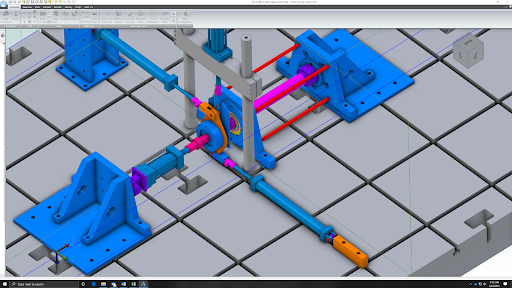

DIC can gather data that other hardware measuring systems cannot; and in a non-contact manner. Some locations are just too hard to install a sensor, let alone gather major measurements as well as measurements in each plane; DIC can. Hundreds of measurements can be taken from the same area one uniaxial gage would require. Instead of the time to adhere, connect, and record thousands of strain gages/ LVDTs/ extensometers/ etc., we can now gather all the information with a nice speckle pattern and a high-resolution camera system.

Authored By: John Muskopf. For more information on this subject or other testing solutions, contact them @ JMuskopf@Metcut.com