About

Our mission at Metcut is to provide our worldwide customers with accurate, reliable, and ingenious materials evaluation and specimen preparation services. We are a full-service firm with significant, world- leading experience in testing materials – metals, intermetallics, composites, ceramics, and coatings – and in evaluating structural behavior.

Our people - educated and experienced

Our people are at the heart of our success and the foundation of our strategy for the future. We believe that long-term, sustained success only results from investment in people. Each member of our workforce is an important financial stakeholder in our business. We know that it is our people who differentiate us in our chosen field of materials evaluation.

Commitment to quality - creating value not just data points

Our team is committed to maintaining the highest level of professional excellence in the services we provide to our customers. We hold ourselves to the finest level of quality in our industry. It is only through this devotion to quality that we can earn the confidence of our clients in the reliability and accuracy of our work.

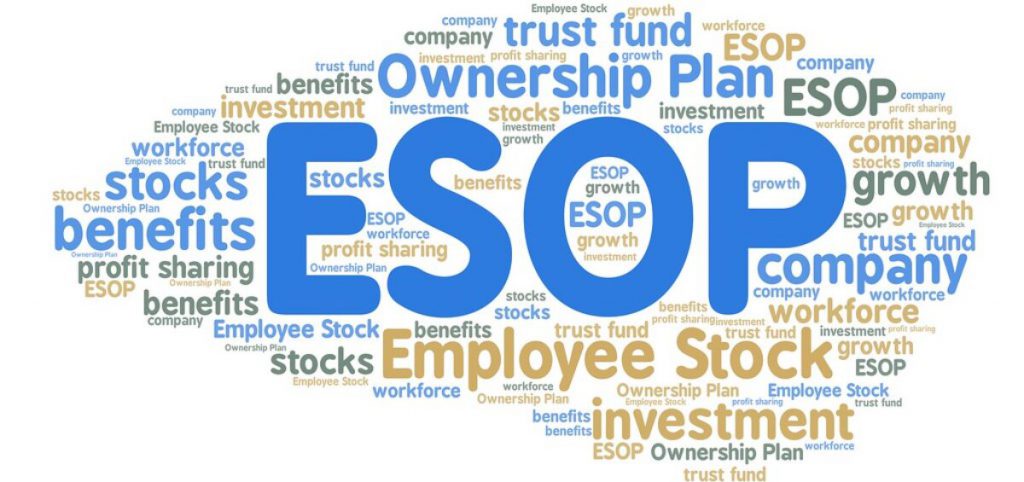

ESOP ownership structure - 100 % employee-owned

We have been an independent company since our beginning in 1948 and an employee-owned (ESOP) enterprise since 1976. As a result, our allegiance always is to our client, not to an outside investor, financial institution, or parent company. Independence is an important quality in attracting and retaining high- performing professionals. This structure also gives us the flexibility to explore and develop customized service solutions without the encumbrances of external influence.

Culture - emphasizing service to clients

Providing consistent, personalized, and high-quality service to our clients has been and always will be our first priority. We look for the most enthusiastic and talented professionals so that our clients will benefit from their knowledge and expertise. We value personal integrity as the basis of developing and maintaining long-term business relationships.

Innovation continually improving and innovating

The services we provide today are the result of past innovations; our services tomorrow will come from our ingenuity today. Incremental continuous improvement gains and great leaps forward both come from diverse, energetic teams who question, imagine, test, refine, and implement.

Education - always pursuing knowledge

We encourage employees to pursue continuing education, believing that this benefits them personally and improves the quality of services to our clients. Every year we make significant investments in the professional development of our employees. Our ongoing investment in continuing education is a commitment toward meeting the goals of our employees and the needs of our customers.

Team

President / CEO

Gregg G. Uebelhor

Vice President

David E. Abeln

Chief Financial Officer, Treasurer and Secretary

Tim M. Germany

MRSAS General Manager

Joachim Galipaud

Engineering Manager

Kenneth J. Kramig

Engineering Manager

Jon W. Fohl

Materials Analysis and Central Coatings Laboratory Manager

Dr. Tri Shrestha

Testing Laboratory Manager

Tony Hardesty

Testing Laboratory Manager

Jason M. Feldmann

Manager Corporate Quality

Jeff S. Viney

Engineering Program Manager

Michael J. Booker

Manufacturing Manager

David D. Bertsch

Manufacturing Manager

Tom Parker

Manager Corporate HR

Nicole T. Ellison

Manager Corporate Accounting

Robert Fohl

Information Systems Manager

Tricia R. Carter

History

Following World War II, three major research activities evolved which had direct and far-reaching impacts on the worldwide metal cutting industry:

The search for better, longer-lasting cutting tool materials

The formulation of more active cutting tool coolants and lubricants

The identification of more effective free-machining additives to ferrous alloys

1948

The 3 founders of Metcut (Dr. Michael Field, Mr. Norman Zlatin, and Dr. John F. Kahles) envisioned an opportunity to develop and disseminate technical information in the science of machinability.

They saw a need for a focal point to collect and organize the numerous research activities occurring simultaneously around the world.

Metcut provided the machining industry with a qualified, independent source for testing, measuring, and evaluating the results of these three research activities.

We helped develop much of the information and techniques for machining metals, including the development of low-stress grinding techniques for high-strength alloys.

Metcut’s Machinability Data Center was the national center for metal cutting data; this information was published by Metcut in the three editions of the Machining Data Handbook.

1971

Cincinnati Testing Laboratories’ Independence from CTL Aerospace

After conducting testing for phenolic resins and the NASA Apollo heat shield as part of the internal/captured laboratory within CTL Aerospace, Cincinnati Testing Laboratories was founded as an independent testing lab. The move allowed CTL to engage in the growing external composite testing sector.

1976

ESOP Formation – 100% Employee Owned

As Metcut always has been an employee-centric company, transitioning to an Employee Stock Ownership Plans (ESOP) was a natural continuation of the corporate philosophy stretching back to 1948. 100% Employee-Ownership provides an absence of external influence allowing us to focus on customer needs, not investor demands.

1992

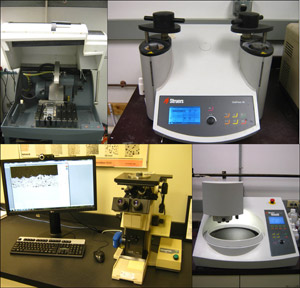

Central Coatings Laboratory (CCL) Established

Over the years, Metcut developed expertise in evaluating and making quality control measurements on thermal barrier coatings. Requests for these services came from many sources, with the bulk coming from GE and its suppliers. After a successful bid to GE on a program to operate what would become the CCL, Metcut help develop procedures and training for GE coating suppliers worldwide. The purpose of this course is to teach supplier’s technicians to uniformly do their own quality control work in their own laboratories while having periodic round robins back to the CCL expert team. The program is still going strong with classes throughout the year.

1994

MRSAS Established in Nantes France

Metcut Rescherches Societie Anonyme was established in response to an invitation by SNECMA, a major fatigue customer for Metcut starting in the 1980’s. Strategically located to serve other European customers in Nantes France, MRSAS incorporated the knowledge of Metcut US and focused primarily on low and high cycle fatigue.

1998

Metcut purchases Cincinnati Testing Laboratories (CTL)

During the 1980’s, CTL evolved as a key player in the development of composite design data for a new of programs in the aerospace industry. CTL had become an internationally recognized for their abilities to manufacture specimens and test aerospace materials including ceramic matrix composites, titanium-aluminides and other intermetallic. To accelerate Metcut’s entrance into the non-metallic market, a strategic, friendly acquisition of the cross-town rival CTL was reached in 1998.

2008

CTL creates purpose-built 43,000 ft2 lab

Outgrowing the original location of CTL on Northland Blvd in Cincinnati, CTL built a purpose-built laboratory space that also served as home for a relocated Metcut Creep lab and the Metcut Matlab/CCL. The new facility located on Carillon Blvd in Forest Park Cincinnati Ohio, contained dedicated laboratories for mechanical testing for composite including thermal on moisture equipment as well a full specimen preparation department. A key features included a large external liquid nitrogen tank to supply the test frames thru vacuum-jacketed lines.

2010

In 2010, ASM International recognized Metcut’s Cincinnati, Ohio headquarters as an ASMI Historical Landmark with the following citation:

“This building, constructed in 1951, was the first facility of Metcut Research Associates Inc. At this location, groundbreaking research was conducted in the areas of machinability and surface integrity”

Our early experience in evaluating the effect of machining tools and methods on the performance of metals evolved into what we are today – the premier independent, employee-owned materials evaluation company worldwide.

Our expertise in mechanical property testing, structural behavior characterization, and microstructural evaluation is recognized throughout the world.

2015

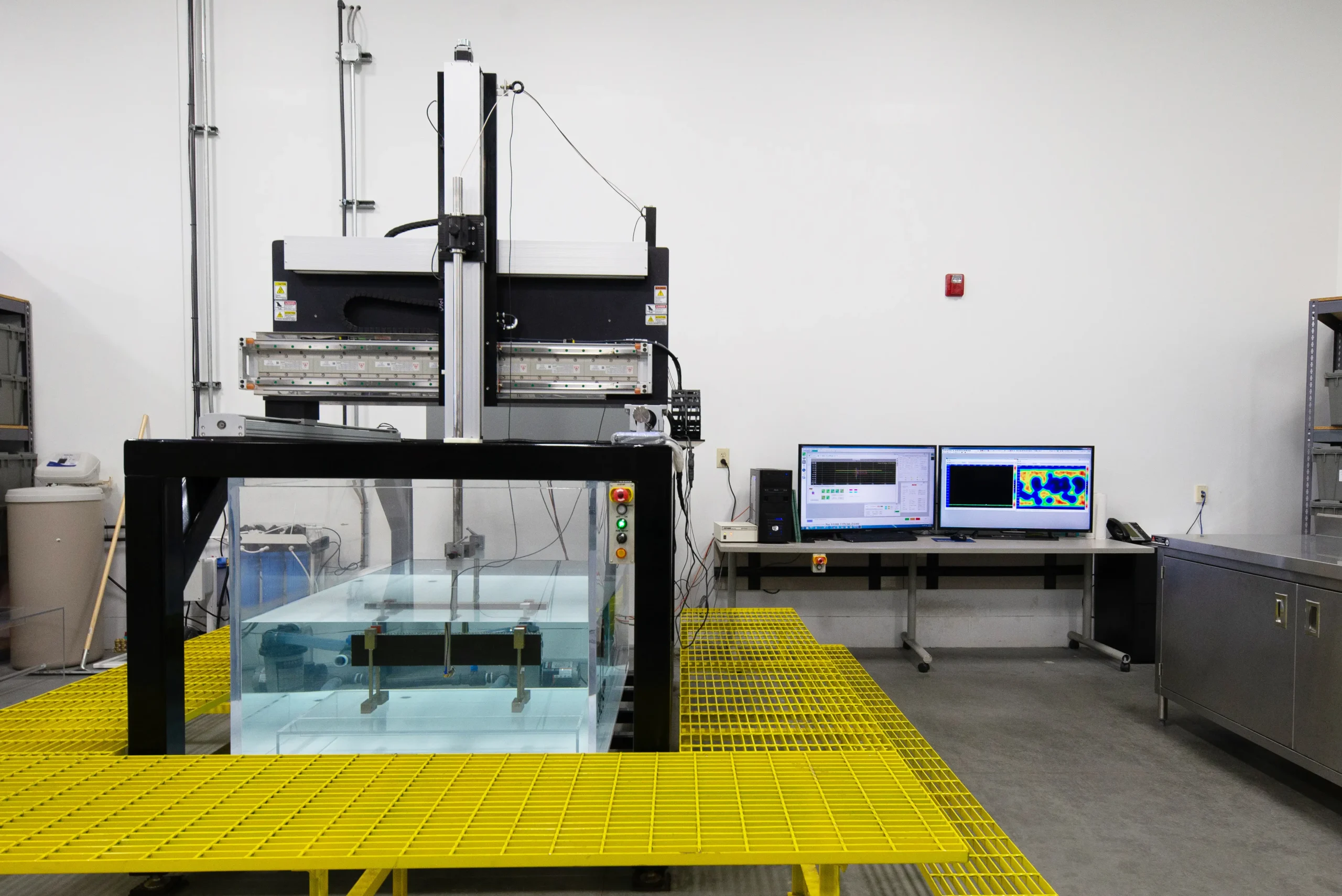

CTL expands by 22,000 ft2

With the continued growth of composite work in the mid-2010’s, the CTL facility expanded by another 22,000 ft2 giving room for four more laboratories spaces for new capabilities like Ultrasonic, walk-in humidity cabinet and more frames.

2016

Metcut Structures lab Expansion with 1,800 ft2 600 Ton Strong Floor

As an extension to Metcut’s core technical strengths, Metcut created a new Structures department along with a dedicated 11,000 ft2 Structures lab space boasting of an 1,800 ft2 600 Ton Strong Floor. This new space allows for very large components and structures to be tested with multiple actuations site.

2025

Metcut France (MRSAS) getting a new home

With the global growth in testing needs in Europe, Metcut France is following the approach of CTL by creating a purpose-built testing facility with the Nantes community. The new facility will start construction in 2025 to be operational in 2026. The move increases the size of Metcut France from 8,000 ft2 to 18,000 ft2 providing for future growth into other modalities of testing beyond fatigue.

To provide the best experience for our customers and increase internal flexibility, it was decided to fully incorporate CTL into the Metcut Research Inc. corporation. Effective July 1st 2025, Metcut Research Inc. will have two operating locations in Cincinnati, Metcut Research Cincinnati – Rosslyn and Metcut Research Cincinnati – Carillon.

Facilities

139,000

ft2

(12,900

m2

)

Of laboratory and machining space in our three locations:

- Metcut Research Cincinnati – Rosslyn in Ohio USA

- Metcut Research Cincinnati – Carillon in Ohio USA

- Metcut Recherches in Nantes France

Many of our services focus on high-temperature materials applicable to turbine engines and power generating equipment. We are adept at evaluating a broad range of metallic, non-metallic, and composite materials from diverse applications including airframes, ground transportation, oil & gas, alternative energy, and biomedical devices.

Accreditations & Approvals

Metcut, CTL and Metcut France have been audited by most major companies in the aerospace, automotive, foundry, nuclear energy, and bio-materials industries worldwide. We have received numerous vendor approvals.

A2LA

- ISO/IEC 17025:2017

- Mechanical Testing

- Metallography & Microhardness

- Hardness

- Specimen Preparation

Metcut

- ISO/IEC 17025:2017 (0296.01)

- Mechanical Testing

- Metallography & Microhardness

- Hardness

- Specimen Preparation

CTL

- ISO/IEC 17025:2017 (0296.02)

- Mechanical Testing (Metals;Non-Metals)

- Specimen Preparation

Metcut France

- ISO/IEC 17025:2017 (0296.03)

- Mechanical Testing

NADCAP

- 215443 – AC7000 – Scope of Accreditation

- 215457 – AC7000 – Scope of Accreditation

- 3511215457 – Materials Testing Laboratories

- 3566210028 – Non Metallic Materials Testing

- 3566215443 – Materials Testing Laboratories

- Metallography & Microhardness

- Hardness

- Hardness

- Mechanical Testing

- Specimen Preparation

- AC 7109 Coating Evaluation

Metcut

- 215443 – AC7000 – Scope of Accreditation

- 3511215457 – Materials Testing Laboratories

- AC7101/3: Mechanical Testing

- AC7101/4: Metallography & Microhardness

- AC7101/5: Hardness

- AC7101/7: Specimen Preparation

- AC 7109/5: Coating Evaluation

CTL

- 215457 – AC7000 – Scope of Accreditation

- 3566210028 – Non Metallic Materials Testing

- 3566215443 – Materials Testing Laboratories

- AC7101: Non-Metallic Material Testing

- AC7101/3: Mechanical Testing

- AC7101/7: Specimen Preparation

Metcut France

- XXXXX – AC7000 – Scope of Accreditation

- 7735201100 – Materials Testing Laboratories

- AC7101/3: Mechanical Testing