About

The Metcut Structures Lab was established in 2003 to support a high-speed train application. Based on that success we expanded to our current purpose-built high bay lab of 10,000 sqft completed in 2015. We provide custom test solutions to meet your product development and certification testing needs, including multi-axis static and dynamic mechanical test, hydraulic and pneumatic pressure test, hydraulic component test, and gearbox endurance and efficiency test. Our capabilities include test system design, tooling design and build, instrumentation application, Digital Image Correlation, ultrasonic A-scan and C-scan, and acoustic emission.

Primary Services

Metcut offers services in many different areas of testing and is always willing to help you tackle your current testing challenges. Below are some examples or our primary test services we offer.

- Static and Fatigue test development and execution

- Test system design, manufacturing, and assembly

- Strain gage installation and recording

- Data Acquisition and handling

- On-Site test system design, assembly, and operation

Types of Testing

Metcut provides services for general Research and Development, qualification, and certification. Most test configurations can be tested in a destructive or non-destructive manner. Some of these types of tests are included below.

- FAA Certification Testing

- Full-scale structural qualification testing

- FEA certification and comparison testing

- Axial, Multi-axis, and Axial-Torsion Testing

- Pressurized Vessel with or without applied external load

- Digital Image Correlation

- Ultrasonic A-scan/C-Scan

- Acoustic Emission

Facilities and Equipment

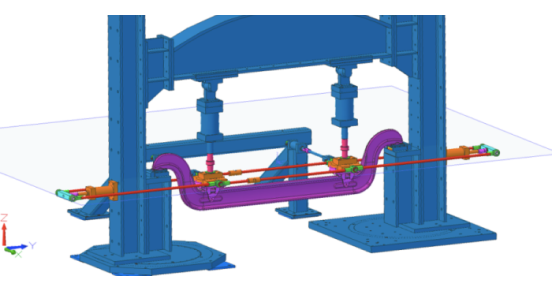

The laboratory is equipped with the latest MTS AeroPro servo-hydraulic control systems. Metcut is very accustomed to building bespoke test stations for unique demands.

- 1800 ft2, 600 Ton Strong Floor

- (3) Strong Walls

- (5) Large Slotted Test Beds

- 100 Kip / 1.2 Million Inch pound axial-torsion Machine

- (50+) Actuators with capacity up to -650,000 / +400,000 lbf

- Pressure vessel equipment capable of 150,000 psi

- (4) MTS controllers with 118 Channels for up to 21 stations

- (4) MTS FlexDAC for recording up to 192 channels of data

- Availability to 115+ single-axis MTS test frames.

- 20-ton overhead crane with 20’ spread beam

- Fork-lifts and other various large rigging equipment